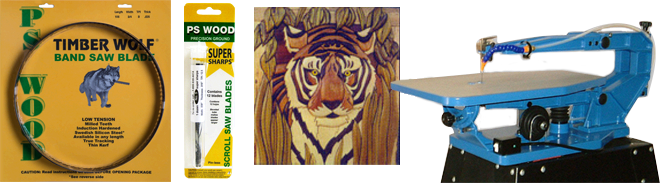

TIMBER WOLF® BAND SAW BLADES

TIMBER WOLF® band saw blades are AVAILABLE IN ANY LENGTH

All our TIMBER WOLF® blades are made as ordered and are cut, welded and packaged in our facility in Bethel Park, PA. Our lead time is 3 business days.

Through the use of premium Swedish steels, proprietary induction hardening methods and exclusive tooth milling processes came some of the finest woodworking blades in the world.

TIMBER WOLF® blades run under low-tension, produce a thin kerf and make remarkable tight turns. Milling the teeth of the blade into a piece of strip steel produces a finished, razor sharp edge without ever having to stamp or grind the teeth. Induction hardening allows for different but more precise hardness throughout the blade. These unique manufacturing techniques along with the use of Swedish Silicon steel set these blades apart from all other carbon based blades. A perfect balance of superior steel, blade width and thickness plus precision set teeth produce a superior cutting blade with exceptional overall life.

WHY CHOOSE TIMBER WOLF® BLADES

-

50% SHARPER TOOTH

Teeth are milled not stamped or crush ground

-

PRECISE HARDENING THROUGHOUT THE BLADE

Induction hardened versus flame hardened

-

EXTENDED SHARP TIME

Tooth edge is 20% harder than any high carbon blade

-

EXTENDED FLEX LIFE

Much more ductile steel than any high carbon steel

-

COOLER RUNNING BLADE

Dissipates heat 3x faster than high carbon steel

-

UTILIZES 20% LESS HORSE POWER

Requires less tension

TIMBER WOLF® BLADE SERIES

PC SERIES – For kiln dried wood

PC = POSITIVE CLAW

available in: 3/16" to 1" wide in many tooth pitches

Most of us would like to keep the tedious labor of planing or sanding to a minimum. Our PC Series of blades is our claim to fame. It is, in its design, everything a wood cutting blade was meant to be. It has over 60% of the speed capabilities that a hook is able to travel at, while at the same time giving you the great finish of a skip. By incorporating a "hook" style geometry in our gullet, we have given our blade the ability for fast chip removal. Due to its round design we have eliminated any work hardening zones in the gullet. Couple all this with our unique 6.5 degree rake angle, combined with our special 5 tooth set pattern (which allows us to reduce the set) and we now have a true "thin kerf", awesome cutting blade that gives you an excellent finish.

AS SERIES - for green or exotic wood

AS = ALTERNATE SET

available in: 3/8" x 3 tpi , 1/2" x 2 tpi and 1/2" x 3 tpi

These small blades are unique in their body thickness, set, and rake angle. They are .032 thick, have an alternate set and a unique rake angle of 6.5 degrees. They also utilize the unique geometry of our PC gullet. These bands are primarily used in furniture industry. They have been designed to cut both fast and accurately in very thick wood such as stacked lumber. Woodturners use these blades to cut turnings out of large burls. Their applications are endless. Their performance is excellent if the thickness of your material exceeds 6 to 8 inches. These blades are not meant to be used on any 3-wheel saw or for that matter any saws with less than 90" blade length or wheel diameter less than 14".

TPC SERIES - for straight line veneer cutting

TPC = THIN POSITIVE CLAW

available in: 3/4" x 3 tpi

This blade's uniqueness lies in the fact that it is only .025 thick with our unique set pattern. The total overall set is less than .048 thousandths of an inch. When you are resawing very expensive woods that are thick and you want as thin a kerf as possible, a super finish, and you are not concerned with speed, this is the blade for you.

VPC SERIES - for straight-line resawing in small to large boards, kiln and air dry, up to 12" wide

VPC = VARIABLE POSITIVE CLAW

available in: *NEW! 1/2" x 2/3 , *NEW! 1/2" x 3/4, 3/4" x 2/3 tpi , *NEW! 1" x 2/3

The variable tooth design reduces resonance throughout the blade; this is combined with different size teeth produces a very clean finish almost polishing the woodas it is cut. It is only .025 thick with an overall kerf of .049 and incorporates the unique geometry of our PC design.

RK & HP SERIES - for detail work

RK = RAKER

HP = HIGH PERFORMANCE

This blade's uniqueness lies in the fact that it is only .025 thick with our unique set pattern. The total overall set is less than .048 thousandths of an inch. When you are resawing very expensive woods that are thick and you want as thin a kerf as possible, a super finish, and you are not concerned with speed, this is the blade for you.

TIMBER WOLF® WIDTHS & TPI

- 1/8" x 14 (HP .025)

- 3/16" x 4 (PC .025), 10 (RK .025)

- 1/4" x 4 (PC .025), 6 (PC .025), 8 (RK .025), 10 (RK .025), 14 (RK .025)

- 3/8" x 3 (PC .025) , 4 (PC .025), 6 (PC .025), 8 (RK .025), 10 (RK .025), 14 (RK .025)

- 3/8" x 3 (AS .032) AS Series

- 1/2" x 2 (AS .032), 3 (AS .032) AS Series

- 1/2" x 2/3 (VPC .025), 3/4 (VPC .025)

- 1/2" x 3 (PC .025), 4 (PC .025), 6 (PC .025), 8 (RK .025), 10 (RK .025)

- 3/4" x 2/3 (VPC .025)

- 3/4" x 3 (TPC .025)

- 3/4" x 3 (PC .032), 6 (PC .032), 10 (RK .032)

- 1" x 2/3 (VPC .035) NEW!

- 1 x 2 (PC .035), 3 (PC .035), 4 (PC .035), 6 (PC .035), 10 (RK .035)