There are no products listed under this category.

DID YOU KNOW?

DID YOU KNOW

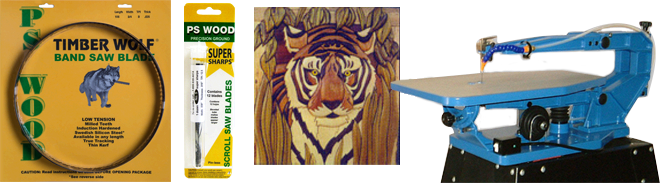

- NOTICE: We manufacture a very special series of LOW TENSION, HIGH DUCTILE, SILICON STEEL BAND SAW BLADES for the woodcutter and sawyer. Our bands run purposely with 35% to 50% less tension than our competitors’ carbon bands. Being very stable at low tension, over 70% of the rotation fatigue effect is eliminated increasing blade body life (flex life) dramatically, and 20% LESS HORSEPOWER IS REQUIRED.

- CHECK YOUR TIRES AND GUIDES. Our silicon steel blades like all other narrow carbon band saw blades 2” and under, run best on a cushion of urethane or rubber. The shock absorbing quality of resilient tires, around the metal band saw wheels, extends blade body life dramatically. Modern band saw wheels have a crown machined across the face of the metal wheel. The crown can be as little as .010 thousands for tracking ¾” and narrower bands, or as much as .030 thousands for tracking 2” bands. This crown causes the effects of self-tracking. It is the same principle used for tracking sanding belts on a belt sander. Age, over tensioning and not detensioning the band after use, compress and flatten the crown out of the tires. This compression and time also will make the tires hard and brittle. OLD TIRES CAUSE BAND BREAKAGE!

- ALWAYS TRY TO KEEP 6 TO 8 TEETH IN THE CUT AT ALL TIMES; this is for metal or woodcutting. It will give you stability and more of an accurate cut when scrolling or straight cutting.

- FATIGUE RATIO OF A BAND SAW BLADE: The stress applied to the blade body; due to wheel diameter, blade length, thickness, speed (surface feet per minute SFPM) and tension. Blade body life diminishes rapidly when put into any one or more of the stress situations listed above. The blade as it travels around the wheel is compressed on the inside of the body, which is closest to the wheel and stretched on the outside of the body. Blades are designed to absorb repeated compression and expansion of the body as long as the compression and expansion does not exceed the steel’s capabilities. Two wheel machines, smaller than 14” wheels, using blades 1/8” – ¾” will encounter 20% to 50% less blade life. With machines 14” or larger, you will see blade life increase proportionally. You will encounter decreased blade life with any 3-wheel saw even if the wheels are larger than 14”.

- EXAMPLES OF OPTIMUM S.F.P.M. ON SPECIFIC WHEEL DIAMETERS. IT IS NOT CONSIDERED WISE TO EXCEED THESE VALUES. (Vertical band saws only)

Diameter S.F.P.M. Diameter S.F.P.M.

12” 2,800 24” 4,000

14” 3,300 26” 4,000

16” 3,800 28” 4,000

18” 4,000 30” 4,000

20” 4,000 36” 4,000

As you exceed the S.F.P.M. on a specific wheel diameter, you are greatly increasing the centrifugal force applied to the body of the band traveling between the two wheels. This causes you to over tension your bands in order to make them run stable. This WILL cause permanent and excessive blade breakage. Band saw blades cannot be tensioned properly if your S.F.P.M. exceeds the above chart. There is also a minimum speed you can run a band saw blade. (Example: Timber Wolf™ band saw blades cannot be run under 2,400 SFPM and Timber Wolf™ mill blades should not be run under 4,000 SFPM)

UNDERSTANDING OUR

BAND SAW BLADES

PC SERIES (Positive Claw) – Most of us would like to keep the tedious labor of planing or sanding to a minimum. Our PC series of band saw blades is our claim to fame. It is, in its design, everything a wood cutting blade was meant to be. It has over 60% of the speed capabilities that a hook is able to travel at, while at the same time giving you the great finish of a skip. The depth and roundness of the gullet increase sawdust removal and cutting speed while the milled teeth help to reduce consumption of horsepower. Couple all this with our unique 6.5° rake angle and special 5 tooth set pattern (which allows us to reduce the set) and you now have a true “thin kerf”, awesome cutting blade. Available in widths of 3/16” through 1” in many tooth pitches for use in kiln dry wood.

AS SERIES (Alternate Set) – These blades are unique in their body thickness, set, and rake angle. They are .032 thick, have a full alternate set, a unique rake angle of 8.5°, and also incorporate the unique geometry of our PC tooth design. These bands are primarily used in the furniture industry. They have been designed to cut both fast and accurately in very thick wood such as stacked lumber. Woodturners and woodcarvers use these blades to rough out blanks from burls and logs. Their applications are endless. Their performance is excellent if the thickness of your material exceeds 6 to 8 inches. These blades are available in 3/8” and ½” widths, with 3 tpi only in lengths over 90”.

AS-S SERIES (Alternate Set Special) – Its uniqueness lies in the fact that it is only .025 thick with a unique set pattern. The total overall kerf is .048. This band was specifically designed for straight-line veneer cutting. When you are resawing very expensive woods that are thick and you want as thin a kerf as possible, a super finish, and you are not concerned with speed, this is the blade for you. Available in a ¾” x 3 tpi only.

RK and HP (Raker, High Performance) – These blades have a very thin kerf and 0° rake angle and are specifically designed for detail work in 1” and smaller kiln dry wood when a very clean finish is required. They are also very effective in plywood, particleboard and other similar products where tear-out is a concern. These blades can also be used to cut soft metals.

NEW VPC (Variable Positive Claw) – Designed for resawing in small to large boards, green or dry, up to 12” thick. The variable pitch tooth design reduces resonance throughout the blade by using different size teeth, which produces a very clean finish almost polishing the wood. It is only .025 thick with an overall kerf of .048 and incorporates the unique geometry of our PC tooth design. This blade is available in ¾” width with 2/3 tpi only in lengths over 90”.

THE 3 RULES OF SAWING

1) THE “FLUTTER TEST” FOR PROPER SILICON STEEL TENSIONING (FOR TURN SCREW AND SPRING TENSIONING MACHINES)

- Turn your saw off and disconnect all power to your saw.

- Remove old blade and clean tires for inspection. Make sure tire surfaces are in good condition. They cannot be hard, flattened out, cracked, brittle or loose.

- Open your guides or blocks and recess the thrust bearing. You cannot run this test if the band saw blade is restricted in any lateral movement.

- Blades are coated with rust proofing material. Please wipe off before use. Mount the blade on the machine and apply the tension to the band that the manufacturer recommends for other steels. While rotating the wheel by hand, adjust the tracking knob until the teeth are running on the center third of the tire.

- Close all covers for safety purposes and plug in your saw.

- Start your saw. NOTE: You will not be cutting any wood. Stand at the head of the machine with your hand on the turn screw tensioner and your eyes on the band saw blade. Very slowly start detensioning by half turns at a time keeping your eyes on the band saw blade. The object is to bring tension of the blade down to a point that the blade starts to flutter (plucked bow). TAKE YOUR TIME.

- When you see the band start to flutter, you have hit ground “ZERO”. Now start ADDING quarter turns of tension SLOWLY, until the band stops fluttering and is running stable again. At this point ADD one half to one full turn more tension. You have now tensioned our blade correctly.

- Shut off the machine and put your guides back in place. Adjust your guides 3/1000 of an inch away from each side of the blade and 1/16 of an inch behind the gullet. (NOTE: Steel blocks cause friction and increase blade temperature. High temperature damages your blade causing breakage. For best results, use bearing guides, Cool Blocks® or make your own blocks.) Next, move your thrust bearing forward to 3/1000 of an inch away from the back edge of your blade. If the thrust bearing is rotating when you turn your saw on, it is too close. The thrust bearing should not rotate until you actually start cutting. Riding the thrust bearing causes friction and increased temperature. You are now ready to begin sawing.

2) CHOOSING THE RIGHT LUBRICATION

- Water is not a lubricant. If you must use water, mix one capful of Pinesol for every gallon of water.

- Always wipe your blades after use.

- For the Mill owner using 1 ¼”, 1 ½”, and 2” bands, not only is water unacceptable as a lubricant, but it will rust the bands causing deep pitting and inappropriate chip swelling. This prematurely destroys the body of the band and its gullets. For proper lubrication mix high adhesion chain saw bar oil, and kerosene or diesel fuel. Apply the solution with a spray bottle to both sides of the band about once every four minutes while the machine is running. When the lubrication is applied, the sound of cutting decreases over 50%. Do not apply again until the sound starts to increase.

- Vertical saws ¾” width and smaller bands, use “PAM” (found in the baking section of your grocery store). Before mounting the blade on the machine, fold a paper towel in fours, spray some PAM in the middle and wipe the blade (both sides). Be sure to have the teeth pointing in the wiping direction so as not to shred the towel or cut yourself.

In both cases, we know for a fact that lubrication of the body of the band increases band life by over 30%.

3) ALWAYS DETENSION YOUR BANDS

- Leaving the blade tensioned can create several problems. First, it can result in your blade breaking prematurely. The next time a blade breaks, examine it carefully. If it didn’t snap at the weld, the break is likely the result of leaving the tension on.

- When you are done cutting for the day, take the tension off your blade. Since you do not know exactly where the proper tension is, it will be easier to remember if you take off 8, 9, or 10 full turns of tension until the band is completely relaxed. The next time you use our bands, add the same amount of turns of tension that were taken off. At this point, you will only have to run the flutter test one time.

- Band saw blades, when warmed from cutting, always stretch, and upon cooling shrink by tens of thousands of an inch each cooling period. Blades, when left on the saw over tension themselves which will cause cracking in the gullet. When you leave the band under tension not only do you distort the crown and flatten your tires, but you place undue stress on your bearings and shafts.