Blade Designation: Scrolling or

Curve, Template and Pattern Cutting

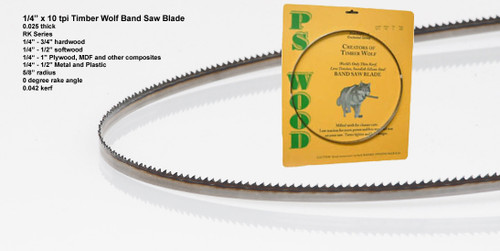

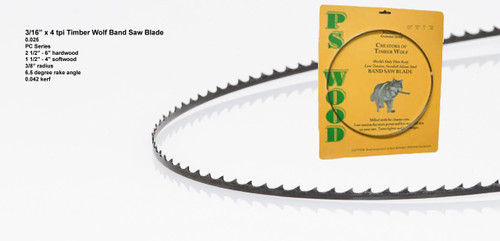

Width: 3/16"

TPI (Tooth Per Inch): 10

Tooth Design: RK (raker)

Blade Thickness: .025

Kerf: .042

Tooth Hook Angle: 0°

Tooth Set Pattern: 5 Raker Set

Radius of Cut: 3/8”

Thickness of Work Material to be cut

Kiln Dry Wood: Hardwood 1/4” – 2 1/2” Softwood 1/4” – 1 1/2”

Plywood, MDF & other Composites: 1/4” – 2”

Soft Metal & Plastic: 1/4" - 1/2″

19 Reviews Hide Reviews Show Reviews

-

Free shipping

I will buy these again. While I had to spend over a certain dollar amount, i got free shipping.

-

Excellent blades, custom sizes work perfectly

I love the Timber Wolf blades. I order custom lengths for my old Montgomery Wards 12" band saw, and have never had any issues at all. I love my machine but it is old and finicky; once I started using these blades the install started going so much easier. Great cut as well. Highly recommend.

-

3/16 inch 10TPI 133inch Bandsaw Blade

Had been looking for this Blade but could not find it. Finally e- mails the company and got the correct contact information. Very happy with their blades.

-

3/16" X 10RK SERIES TIMBER WOLF® BAND SAW BLADE

Makes great cuts and sharper curves.

-

Found the blade I need!

I have been switching between 1/8 inch and 1/4 inch blades. The 1/4 wouldn't make the radius I needed and the 1/8 couldn't cut straight. This 3/16 is the ticket! I can now cut out a peg head in one pass and the cut is plenty smooth for what I'm doing.

-

OUT PERFORMS ALL 3/16INCH BANDSAW MFG.

tHIS BLADE IS TRULY A TOUGH AND RESILIENT BLADE.. iT CUTS A LESS THAN 1/2 INCH CORNER IN MY CROSSES THAT i MAKE. IT WILL CUT OVER 100 CROSSES UNTIL IT EARS OUT, NOT BREAK WHICH IS 2-3 TIMES LONGER THAN ANY OTHER BLADE THAT I HAVE USED..

-

Ohio Woodcarver

This is the only blade I use to rip a 2" X 2 " Basswood diagonally. It leaves a smooth cut. I'm pleased with the life of the blade.

-

Finally found a Quality blade

I have an old 16" Delta band saw and its hard to find parts for it, including the blades. Recently I purchased two 3/16"X 10RK series blades for some three dimensional toys I was trying to cut using 2x4 lumber.The blades I got from PS WOOD came through exceedingly well! Very surprised, but happy. Thanks PS Wood.

-

Great Customer Service and Product

Customer service very responsive to helping me change the ordered length. Also, I have 3 different blades and all are excellent. Don;t worry about the product quality, it is fantastic!